Maximum quality for high volumes

G5

5 axes with continuous interpolation. Dry and wet milling.

Specifically developed for the Italian dental industry, consisting of a large number of relatively small laboratories, it is a universal machine, capable of creating any type of article (crowns, bridges, screw-retained bridges, abutments, connection bars, connections, surgical guides, etc.) in all materials (wax, PMMA, different resins, composite, pre-sintered zirconium oxide and aluminium oxide, hydroxyapatite, titanium (gr2 and gr5), Co-Cr alloy.

- Find out about the G5

- Winning characteristics

- Granite structure

- Cone handling

- Machining

Granite base

5 continuous axes

Dry and wet milling

19-position tool magazine

Electronically controlled brushless motors

- Precision

- Repeatability

- Machinable materials

Universal milling machine for the dental sector.

Winning features

Pre-configured to mill 24/7, the G5 has a sturdy, oversized construction to support any stress and workload of a large milling centre.

Spindle with 2.1 kW of maximum power at 50,000 rpm

German manufacturer, market leader: guarantee of quality, performance and durability for excellent milling results at both low and high speed.

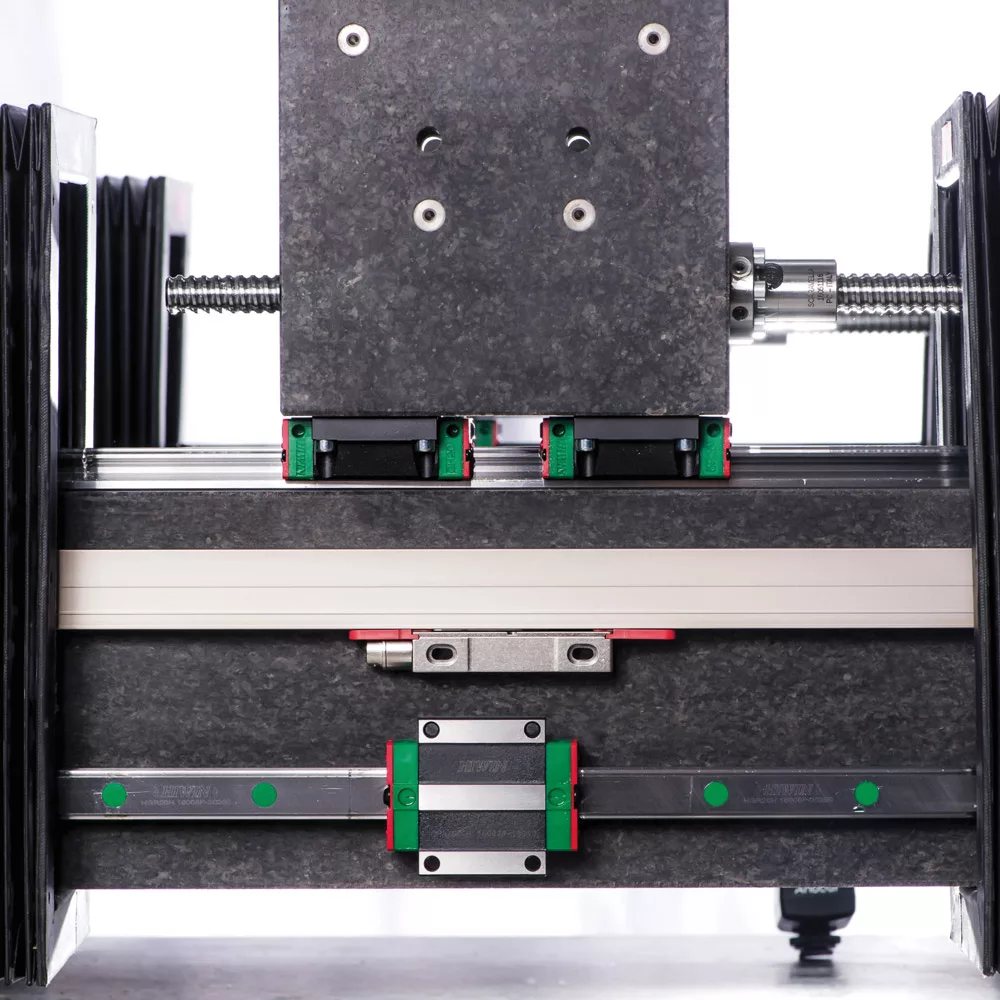

Granite supports on all three Cartesian axes

A device such as a milling machine, used to create high-precision articles with a high production rate, must be sturdy, robust and capable of handling more than the actual workload.

Heidenhain linear encoders on 3 Cartesian axes

Linear encoders detect the actual position of the axes with an accuracy of 1 micron (0.001 mm).

Free, open system

Use of standard file formats both in input and output to give the client the freedom to choose other equipment. No constraints in the use of specific materials and/or tools.

Built to last

The only one with granite on all three axes

The G5 is the only milling machine for the dental industry that does not have only the base but all three Cartesian axes made of black granite from South Africa (machined in Italy), a guarantee of both precision and stability.

- Excellent dimensional stability: material with no internal tensions

- Excellent thermal stability: linear dilation coefficient much lower than cast iron and steel

- Excellent wear resistance

Built to last

Granite: to ensure repeatability and durability

- Greater hardness than tempered steel (6-7 on the Mohs scale)

- Resistance to acids and oxidation; non-magnetic and electrically insulating

- Granular matrix that absorbs vibrations with no high resonance frequency

- This material, which Dental Machine uses on the 3 Cartesian axes, gives the machine greater precision, stability and durability

Maximum reduction of vibrations

Any tool that machines hard material (e.g. cobalt-chrome, titanium, etc.) produces a wide range of vibrations, some of which can cause the support structure to resonate, leading to a loss in precision, increased tool consumption and wear and tear on machine parts over time. The use of granite solves this problem at its root.

Precise tool assembly

Cone handling

The electrospindle does not pick up the tool directly – this is done by an adjustment cone, fitted with a precision tool holder clamp ER16 (φ shaft from 1 to 10 mm). The tools on cones are assembled on the workbench, with greater alignment accuracy (tool supplied).

- Greater torque absorption

- Maximum static and dynamic rigidity

- Improved repeatable precision in tool changeover

- Lower tool eccentricity

Better metal milling surface, better tool performance.

Great versatility

Dry and wet milling

Wet milling

The milling of hard materials such as titanium and Cr-Co requires lubrication; the machine is equipped with two filters and a tank with a close circuit water pump. The liquid level is displayed on the PC tablet.

Dry milling

When milling materials such as zirconium oxide, it is better to mill it dry, however, the resulting dust can damage moving parts. The machine is, therefore, equipped with watertight protective bellows on all axes. The connection to the central vacuum system prevents dust from escaping into the environment.

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Download

Download the relevant Digital Workflow brochure.

Download the Digital Workflow brochure

Milling technology

Reasons for 5 axes

In modern implantology, which places implants in the best position and angle, milling can only be done in 5 axes. In fact, in space, a segment (which represents an implant) is defined by the 3 Cartesian coordinates plus two tilt axes. Even in traditional jobs, 5 axes are still useful because they allow the prosthesis to be milled to be placed in the blank with the optimum angling, minimising the thickness required; this results in greater speed and less material and tool consumption.