Compact 5-axis milling machine

Vector

Next-generation performance in a compact design

Vector is Dental Machine’s mid-range milling machine, developed for dental labs that want to make the most of CAD-CAM technology and have a high return on investment. It is a user-friendly desk milling machine with numeric control with 5 axes with continuous interpolation.

15.6’” monitor

Compact design

5 continuous axes

Axis angle up to ±30°

18 tools shaft 6mm

15.6” touchscreen monitor

Built-in camera

- Precision

- Repeatability

- Machinable materials

5 axes with continuous interpolation

Winning features

Vector is Dental Machine’s mid-range milling machine, developed for dental labs that want to make the most of CAD-CAM technology and have a high return on investment. It is a user-friendly desk milling machine with numeric control with 5 axes with continuous interpolation.

3.2 KW high frequency electrospindle

Thanks to the 3.2 KW 60,000 rpm electrospindle, it is possible to machine any “hard” material on any type of milling operation.

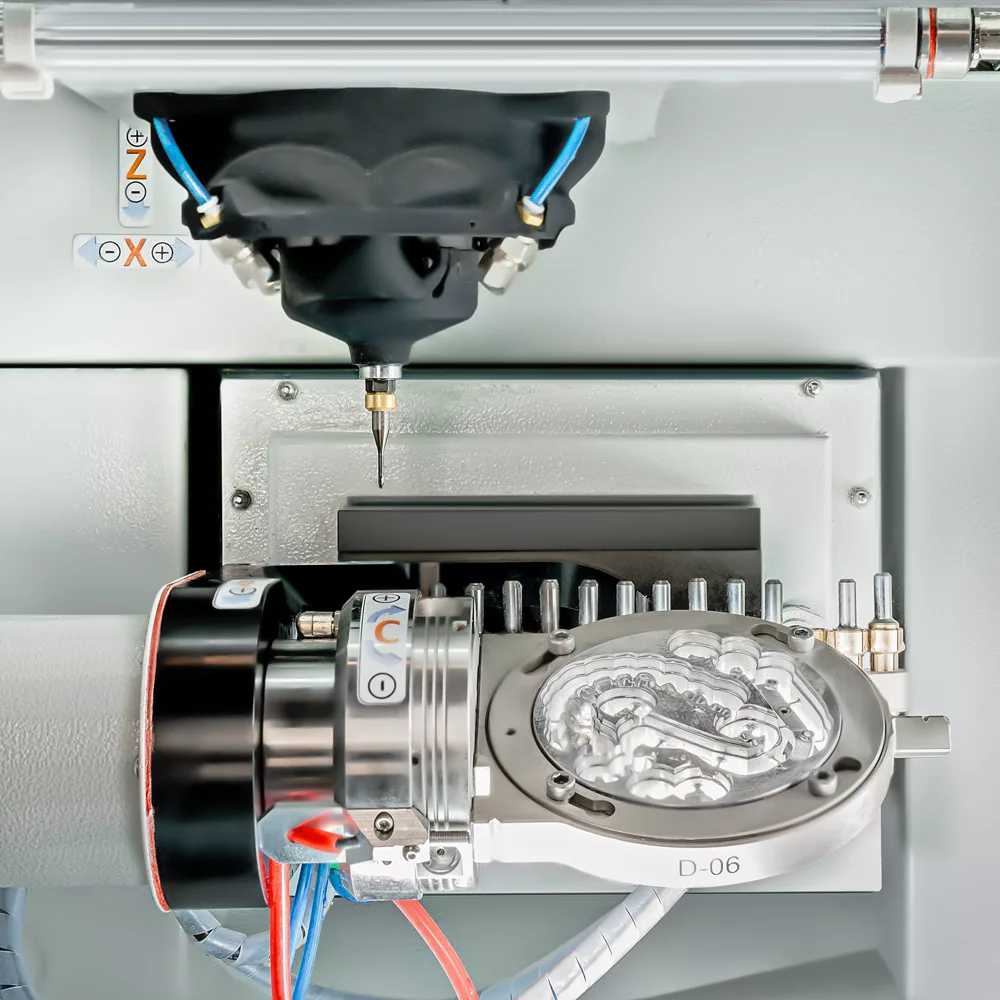

18 tools shaft 6mm

18 tools with automatic changeover with high-precision sensor measurement and verification technology.

Axis angle up to ± 30°

Thanks to the up to ±30° angle of the spindle, Vector can complete highly complex machining with high undercuts.

Machinable materials

It can mill all soft materials such as wax, PMMA, presintered CrCo and PEEK, as well as harder materials such as glass ceramics, composites, cobalt chrome and titanium.

Movements on 5 axes

Linear movement on 3 Cartesian axes with ballscrews driven by brushless motors with absolute encoders for continuous position control while the 2 rotary axes use the same motors with low-backlash planetary gearboxes.

Wet milling

The machining of hard materials such as titanium and Cr-Co requires lubrication; the machine has two filters and a tank with a close circuit water pump.

Dry milling

The machine has watertight protective bellows on all the axes. Connection to the central vacuum system prevents dust from escaping into the environment.

Any material, any format, no constraints.

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Great versatility

Vector Loader

Milling machines with automatic disc change system.

The goal of today’s companies is to respond efficiently and more quickly to market changes and needs. With this logic, Tecno-Gaz and Dental Machine have combined their resources to develop a project for the evolution of their milling machines portfolio.

VECTOR LOADER is the union between the efficiency of the VECTOR milling machine and the productivity of a disc loader (LOADER) which allows the continuous processing (Up to 10 discs) of all the materials available on the market today starting from the softest materials such as Wax, PMMA, Zirconia and Pre-sintered Metal to the hardest materials such as Composite, Glass Ceramics, Titanium and Cobalt-Chrome.

Vector Loader comes by default with 5 holders.

Download

Download the relevant Digital Workflow brochure.